- Home Page

- Company Profile

-

Our Products

- Sewage Treatment Plant

- Waste Water Plant Equipments

- Lamella Clarifier OR Parallel Plate Separator

- Clarifier Mechanism

- Static Mixers

- Pressure Sand Filters

- Oil Water Separator

- Self Cleaning Filter

- CPI Separator Coalescing Plate Interceptor

- Floating Surface Aerator and Fixed Aerators

- Tube Settler Systems

- Automatic Mechanical Step

- Oil Skimmer

- Floating Aerators

- HD Disc Diffuser

- Fixed Low Speed Surface Aerator

- Floating Surface Aerator

- Online Mixing System

- Stirrer Agitator

- Dual Media filter

- Activated Carbon Filter

- Underground Sewage Treatment Plant

- Horizontal Pressure Filter

- Mechanical Bar Screen

- Effluent Treatment Plant

- Waste Water Treatment Plant

- Dissolved Air Flotation

- Contact Us

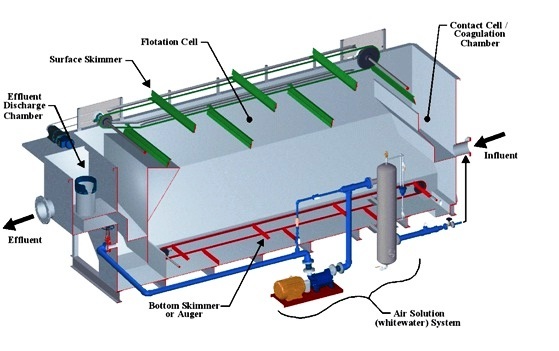

Dissolved Air Flotation

500000.00 INR/Set

Product Details:

- Power Consumption 2 Horsepower (HP)

- Material SS 316/SS 304

- Purity Level 98%

- Voltage 440 Volt (v)

- Drive Type Electric

- Power Source Electric

- Automatic Grade Semi Automatic

- Click to view more

X

Dissolved Air Flotation Price And Quantity

- 500000.00 INR/Set

- 1 Set

Dissolved Air Flotation Product Specifications

- SS 316/SS 304

- Automatic / Manual

- 98%

- 440 Volt (v)

- 2 Horsepower (HP)

- Electric

- Electric

- Semi Automatic

Dissolved Air Flotation Trade Information

- NHAVASHEVA

- Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Cheque

- 50 Set Per Year

- 4-6 Week

- Contact us for information regarding our sample policy

- STANDARD EXPORT PACKING

- Australia Africa Central America North America Western Europe Eastern Europe Middle East South America Asia

- All India

Product Description

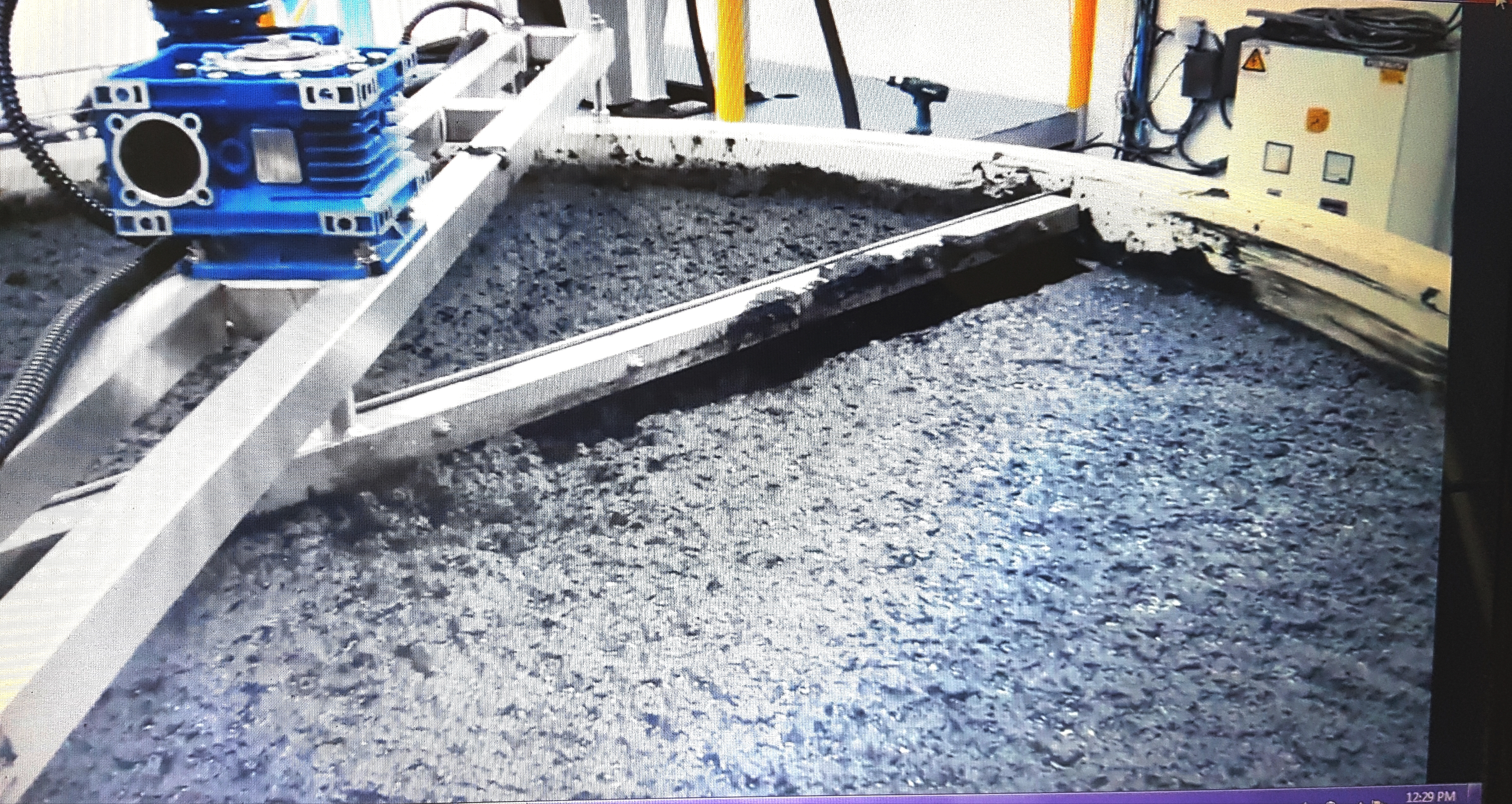

We are a leading manufacturer and exporter of Dissolved Air Flotation (DAF) systems. Our DAF systems are built with superior quality stainless steel (SS 316/SS 304) for a longer service life and are designed for a wide range of applications. The system is semi-automatic and is powered by a 440 Volt (v) electric motor with a power consumption of 2 Horsepower (HP). It has a purity level of 98%. The system works by using a process of dissolving air in the water to form tiny bubbles which attach to the suspended particles in the water. This causes the suspended particles to float to the surface, which is then skimmed off. This process is highly efficient and cost-effective. Our DAF systems are ideal for applications such as wastewater treatment, industrial process water treatment, and oil and grease removal. It is also suitable for treating water for reuse and recycling. The system is easy to install and maintain and is available in a range of sizes and capacities.

FAQs of Dissolved Air Flotation:

Q: What is Dissolved Air Flotation?

A: Dissolved Air Flotation (DAF) is a process of using a process of dissolving air in the water to form tiny bubbles which attach to the suspended particles in the water. This causes the suspended particles to float to the surface, which is then skimmed off.Q: What materials are used for the DAF systems?

A: The DAF systems are built with superior quality stainless steel (SS 316/SS 304) for a longer service life.Q: What is the power consumption of the system?

A: The system is powered by a 440 Volt (v) electric motor with a power consumption of 2 Horsepower (HP).Q: What are the applications of DAF systems?

A: The DAF systems are ideal for applications such as wastewater treatment, industrial process water treatment, and oil and grease removal. It is also suitable for treating water for reuse and recycling.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email